Bioprocess Engineering and Biocatalysis

Bioprocess Engineering and Biocatalysis aims to design and develop value-added bioproducts with potential application in key areas, such as food and feed, cosmetics, fragrances and perfumes, pharmaceutical industry and biofuels. Research is focused on the production, purification and stabilization of proteins/enzymes and on the design of improved bioconversion processes.

Research Projects

Protein Stabilization

Research is focused on the identification of the mechanisms underlying protein stability decay, as well as on the development of suitable approaches to enhance the stability of proteins/enzymes, in order to improve their performance and adapt them to specific industrial and diagnostic applications. Conformational changes and unfolding of proteins under different conditions are assessed by fluorescence and circular dichroism (CD). Strategies for biomolecules stabilization encompass either the use of libraries of affinity ligands or micro/nano-encapsulation of the biological agent:

![]() Cutinase from Fusarium solani pisi, is the model-system for a new approach to assess and enhance protein stability based on the use of synthetic affinity ligands as a novel protein-stabilising tool. The regions in which the thermal unfolding of cutinase is likely to initiate have been identified, and this knowledge was used as the basis for the rational design of solid-phase combinatorial libraries of triazine-scaffolded affinity ligands directed towards the surface of cutinase. Ligand libraries are screened for binding and improving the stability of the enzyme.

Cutinase from Fusarium solani pisi, is the model-system for a new approach to assess and enhance protein stability based on the use of synthetic affinity ligands as a novel protein-stabilising tool. The regions in which the thermal unfolding of cutinase is likely to initiate have been identified, and this knowledge was used as the basis for the rational design of solid-phase combinatorial libraries of triazine-scaffolded affinity ligands directed towards the surface of cutinase. Ligand libraries are screened for binding and improving the stability of the enzyme.

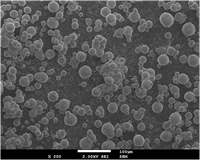

![]() Encapsulation provides a protective environment to the biological agents (enzymes) and allows the production of reusable biocomposites, with high homogeneity and uniform distribution of the biological agent, with high operational and storage stability, and easily harvested from the bioconversion medium. Different strategies for capsule formation are addressed, mostly based in biocompatible hydrogels, namely sol-gel matrices, preferably with magnetic properties, and polyvinyl alcohol based capsules. Dedicated efforts are made to minimize the loss of intrinsic catalytic activity during immobilization procedures, common in sol-gel supports, to have a deeper insight on the mechanisms underlying enzyme stabilization within the immobilization matrix, mostly assessed by fluorescence, and to a rational selection of suitable compounds/conditions that are likely to enhance enzyme stability.

Encapsulation provides a protective environment to the biological agents (enzymes) and allows the production of reusable biocomposites, with high homogeneity and uniform distribution of the biological agent, with high operational and storage stability, and easily harvested from the bioconversion medium. Different strategies for capsule formation are addressed, mostly based in biocompatible hydrogels, namely sol-gel matrices, preferably with magnetic properties, and polyvinyl alcohol based capsules. Dedicated efforts are made to minimize the loss of intrinsic catalytic activity during immobilization procedures, common in sol-gel supports, to have a deeper insight on the mechanisms underlying enzyme stabilization within the immobilization matrix, mostly assessed by fluorescence, and to a rational selection of suitable compounds/conditions that are likely to enhance enzyme stability.

Highthrouput Bioprocessing Optimization

The goal is to accelerate the development of biotransformation systems and investigate the engineering aspects of mini-bioreactors. Contributions are made to the high-throughput development of biotransformation based on mini-bioreactors platforms (200 ml -100 ml). Non-pathogenic mycobacteria are screened and used as workhorses for the synthesis of metabolites useful as building blocks. The methodology developed is used to optimize the productivity of the model bioconversion. Particular efforts are given to contributing to the understanding of hydrodynamics and mass transfer characteristics of non-conventional biotransformation systems, namely involving relatively viscous solvents (viz. phthalate, silicone), to the assessment of key operational features when system requiring prolonged incubation periods are evaluated, and to the identification of the criteria that allow for reproducibility throughout scales

Biocatalysis

The use of enzyme-based processes is widespread among modern day societies. The high selectivity and the ability to operate at lower temperatures while producing less toxic waste, fewer byproducts and less emissions when compared with conventional chemical processes renders biocatalysts extremely useful. Research is focused on the development of strategies for the design and implementation of innovative bioconversion systems. Different enzyme platforms have been developed:

![]() Bio-Esterification SynThesis (BEST)

Bio-Esterification SynThesis (BEST)

An enzyme technology platform based on cutinase and engineered mutants is explored to address 3 major topics in ester biosynthesis: aroma and flavours, biodiesel, macrocyclic esters, and pure chiral compounds. The research focus is on the selection of cutinase and mutants thereoff with high activity and stability in non-conventional media (solvents and surfactants). Enzyme encapsulation or immobilization will be investigated to select the most appropriate enzyme technology platform, biocatalyst and reactor, for each one or the successful applications of the topics highlighted above;

![]() An enzyme technology platform based in the use of commercial inulinase preparations immobilized in selected support materials. Such platform is the basis for the design bioconversion systems for the production of invert sugar syrup and fructose/oligofructose syrups, which can be realistically transposed to commercial scale. Key features addressed are the features underlying the tunability of the single biocatalyst developed for the different product aimed, assessment of suitable activity/stability features, development of suitable predictive models for the bioconversions under study, and preliminary economic evaluation of the bioconversion process;

An enzyme technology platform based in the use of commercial inulinase preparations immobilized in selected support materials. Such platform is the basis for the design bioconversion systems for the production of invert sugar syrup and fructose/oligofructose syrups, which can be realistically transposed to commercial scale. Key features addressed are the features underlying the tunability of the single biocatalyst developed for the different product aimed, assessment of suitable activity/stability features, development of suitable predictive models for the bioconversions under study, and preliminary economic evaluation of the bioconversion process;

![]() An enzyme technology platform based on penicillin acylase is being developed for the production of intermediated compounds (6-APA, 7-ADCA) involved in the chemical synthesis of semi-synthetic b-lactam antibiotics. The enzymatic systhesis of these antibiotics is also being explored as a new green chemistry manufacturing process. Research is focused on the development of stabilization and immobilization strategies that allow the production of stable and cheap biocatalysts.

An enzyme technology platform based on penicillin acylase is being developed for the production of intermediated compounds (6-APA, 7-ADCA) involved in the chemical synthesis of semi-synthetic b-lactam antibiotics. The enzymatic systhesis of these antibiotics is also being explored as a new green chemistry manufacturing process. Research is focused on the development of stabilization and immobilization strategies that allow the production of stable and cheap biocatalysts.

Whole Cell-Based Biotransformations

Microbial cells play a major role in the development of environmentally friendly processes for the production of chemicals. Unlike isolated enzymes, the unique catalytic abilities of given microorganisms can be used without the need for costly and time consuming preparative steps. Moreover, enzymes are protected from the outer environment, thus providing a more stable biocatalyst in the long-term, when compared with free enzymes. Since they harbor metabolic pathways, whole cells are also preferred biocatalysts when multi-step or red-ox bioconversions are envisaged. Swift advances in life sciences and related technology has also been shown to allow for the design of novel and highly performing whole cell biocatalysts. Combining these features with the ease of handling, microbial cells emerge as commonly used tools for industrial purposes.

![]() Diverse catalytic pathways of non-pathogenic mycobacteria are advantageously used in order to produce intermediate products for the pharmaceutical industry, using cheap raw materials as substrates. Focus is given in the bioconversion of cyclic hydrocarbon like molecules, particularly steroids, their ring structure being prone to generate chiral centers, hence favoring the production of unwanted isomers when a chemical synthetic pathway is envisaged. Along with the screening of suitable catalytic pathways, research efforts are made in the understanding on the mechanisms underlying biocatalyst stability and behavior in the presence of organic solvents/ionic liquids, namely at the cell wall level, since bioconversions are often performed in non-conventional media. Within such scope, development of overall criteria for solvent selection and predictive models of biocatalyst behavior in such environments is also envisaged. The ability of the genus Mycobacteriom for de-novo synthesis of siderophores has also been screened, aiming to pinpoint overproducing strains.

Diverse catalytic pathways of non-pathogenic mycobacteria are advantageously used in order to produce intermediate products for the pharmaceutical industry, using cheap raw materials as substrates. Focus is given in the bioconversion of cyclic hydrocarbon like molecules, particularly steroids, their ring structure being prone to generate chiral centers, hence favoring the production of unwanted isomers when a chemical synthetic pathway is envisaged. Along with the screening of suitable catalytic pathways, research efforts are made in the understanding on the mechanisms underlying biocatalyst stability and behavior in the presence of organic solvents/ionic liquids, namely at the cell wall level, since bioconversions are often performed in non-conventional media. Within such scope, development of overall criteria for solvent selection and predictive models of biocatalyst behavior in such environments is also envisaged. The ability of the genus Mycobacteriom for de-novo synthesis of siderophores has also been screened, aiming to pinpoint overproducing strains.

![]() Biodesulfurization of crude oil allows for the reduction of acid rain and air pollution due to the release of sulfur oxides during the combustion of fossil fuels, as well as for significant cost savings in the processing of crude oils for sulfur removal, by avoiding the need of fractionation prior to such process. Mycobacteria and rhodococci are among the microorganisms more commonly used for biodesulfurization. Focus is given to screening for selection of suitable microorganism and operational conditions for sulfur removal from crude oil. The latter feature comprises the identification of a suitable matrix and procedures for whole cell immobilization, and the design of a highly effective bioconversion system. A detailed insight of a suitable biodesulfurization process for large scale application is envisaged as the outcome of this project

Biodesulfurization of crude oil allows for the reduction of acid rain and air pollution due to the release of sulfur oxides during the combustion of fossil fuels, as well as for significant cost savings in the processing of crude oils for sulfur removal, by avoiding the need of fractionation prior to such process. Mycobacteria and rhodococci are among the microorganisms more commonly used for biodesulfurization. Focus is given to screening for selection of suitable microorganism and operational conditions for sulfur removal from crude oil. The latter feature comprises the identification of a suitable matrix and procedures for whole cell immobilization, and the design of a highly effective bioconversion system. A detailed insight of a suitable biodesulfurization process for large scale application is envisaged as the outcome of this project

Biosensors

Research is focused on the design of new protein-ionic-conducting-based biocompatible materials with tailored-made properties.

![]() SpinChip Biosensors

SpinChip Biosensors

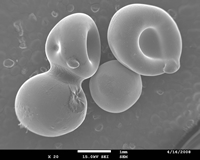

This projects that results on a close collaboration with INESC-MN aims to develop a microfluidic prototype for monitoring pathogen in water such as Salmonella and Escherichia coli based on Magneto-resistive biosensors. These highly sensitive sensors are designed to detect biomolecules (e.g. oligonucleotides and DNA) and cells which are labelled via biomolecular recognition to supermagnetic micro- or nano-beads modified with complementary bioligands.

![]() Ion Jelly Biosensors

Ion Jelly Biosensors

New protein-ionic-conducting-based biocompatible materials with tailor-made properties are designed to build new planar amperometric biosensors based on peroxidases, dehydrogenases and oxidases (e.g. glucose, lactate and alcohol) and molecular recognition of DNA, RNA and antigens by labeling with complementary bioligands (e.g. oligoprobes or antibodies conjugated with peroxidase). The development of these new conducting materials with efficient direct electron transfer between the biological element and the transducer, the Ion Jelly, is expected to open a window of new opportunities for biosensor applications in chemistry and biology.

Research Projects: